Industrial robotics automation has revolutionized the way industries operate, offering a wide range of benefits and advantages.

In this article, we will delve into the concept of industrial automation, exploring the role of robotics in industrial processes.

We will discuss the benefits such as reduced operating costs, improved productivity, enhanced quality, increased flexibility, and enhanced safety measures.

We will also address the challenges and disadvantages of industrial automation, while looking ahead at the future of automation and robotics in the industry.

Stay tuned to learn more about industrial robotics automation and its impact on the industrial landscape.

Key Takeaways:

Introduction to Industrial Robotics Automation

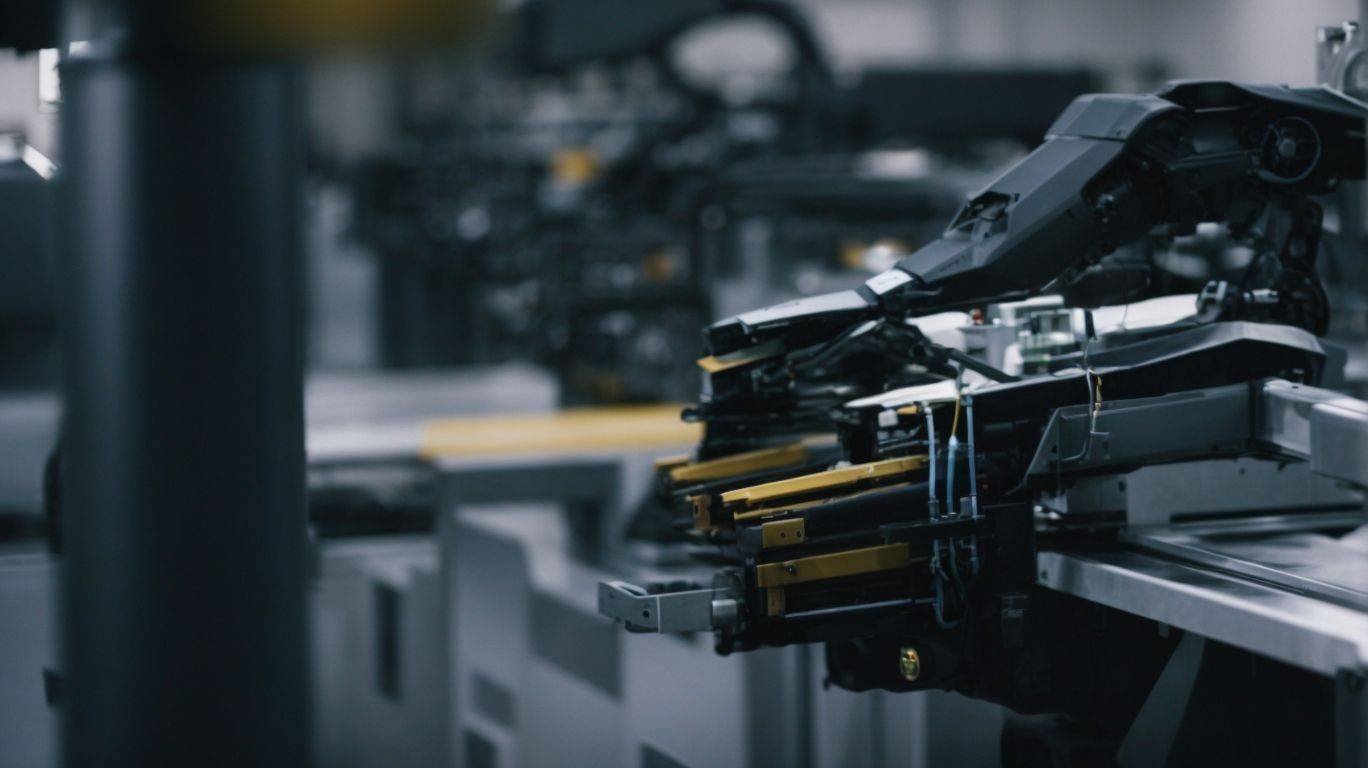

Industrial Robotics Automation is a transformative technology that integrates robotics into industrial processes for enhanced productivity and efficiency.

One of the key benefits of industrial robotics automation is the ability to increase production capacity while maintaining consistent quality standards. Through the utilization of advanced sensors, machine learning algorithms, and Artificial Intelligence (AI), robotic systems can adapt to varying manufacturing conditions in real-time, improving overall operational performance.

Moreover, industrial robotics automation plays a crucial role in enhancing workplace safety by assigning hazardous tasks to robots, thereby reducing the risk of injuries for human workers. This technology is widely utilized in industries such as automotive manufacturing, electronics, and food processing, where precision and speed are paramount.

Understanding the Concept of Industrial Automation

Industrial Automation involves the use of technology and control systems to automate tasks and processes in manufacturing and industrial operations.

This technology-driven approach encompasses a wide range of functions, such as machinery control, production line monitoring, material handling, quality control, and even decision-making processes. By incorporating automation solutions, businesses can achieve higher levels of efficiency, accuracy, and consistency in their operations.

One of the key applications of industrial automation is in the automotive industry, where robots are extensively used for tasks like welding, painting, and assembly. The implementation of automated systems not only enhances productivity but also ensures a safer working environment for employees.

Exploring the Role of Robotics in Industrial Processes

Robotics plays a vital role in industrial processes by offering advanced technology solutions with precise control systems to optimize operational functions.

One of the key aspects of robotics in industrial settings is its ability to perform repetitive tasks with high precision, reducing the margin of error and enhancing overall quality. With the integration of artificial intelligence and machine learning, modern robotics systems are becoming more autonomous, capable of adapting to dynamic environments and improving decision-making processes. This not only boosts operational efficiency but also ensures a safer working environment for employees.

Robotics enables industries to streamline manufacturing processes, accelerate production timelines, and respond quickly to market demands. By leveraging robotics, companies can achieve cost savings, drive innovation, and stay competitive in today’s fast-paced market landscape.

Benefits of Industrial Robotics Automation

Industrial Robotics Automation offers numerous benefits to manufacturers, including improved productivity, enhanced quality, and cost efficiencies.

One of the key advantages of incorporating industrial robotics automation in manufacturing is the significant boost in productivity. Robots can perform repetitive tasks with great precision and speed, leading to faster production cycles and increased output. This not only reduces lead times but also enhances overall operational efficiency. Robotics automation plays a crucial role in ensuring consistent and high-quality outputs by eliminating human errors and variations in tasks.

Automation in manufacturing processes results in better quality control as robots can accurately perform intricate operations, leading to products of consistent quality. This level of precision minimizes defects and waste, ultimately improving customer satisfaction and brand reputation.

From a cost perspective, industrial robotics automation can lead to cost savings in the long run. Though the initial investment may be significant, the reduced labor costs, lowered error rates, and increased throughput ultimately result in improved cost efficiencies for manufacturers.

Reduced Operating Costs

One of the key benefits of industrial robotics automation is the reduction in operating costs through streamlined automation of tasks and processes.

By implementing industrial robotics automation, companies can significantly lower their expenses by reducing the need for manual labor, minimizing errors, and enhancing productivity.

Moreover, automation optimizes production lines by ensuring consistent quality and efficiency, leading to higher output levels and improved overall performance.

Through the integration of sensory feedback and AI algorithms, robots can adapt to changing conditions, making them versatile and adaptable to various manufacturing environments.

Improved Productivity

Industrial robotics automation significantly enhances productivity for manufacturers by automating processes and providing efficient solutions.

This technology has revolutionized manufacturing industries, allowing for streamlined production lines and reduced human error rates. By utilizing sophisticated robotic systems, companies can achieve higher output levels while maintaining consistency in quality. Industrial robotics automation optimizes assembly tasks, material handling, and packaging operations, leading to cost savings and improved competitiveness in the global market.

Enhanced Quality

Quality control is enhanced in manufacturing processes through industrial robotics automation, ensuring consistent output and adherence to standards.

Industrial robotics play a crucial role in maintaining the desired level of precision and efficiency in manufacturing operations. These automated systems can perform repetitive tasks with unparalleled accuracy, significantly reducing the margin of error. By utilizing advanced sensors and data analytics, robotics ensure that each product meets the specified quality criteria, eliminating deviations and defects. Moreover, automation not only enhances production speed but also facilitates compliance with industry regulations and safety protocols, providing a reliable and controlled environment for manufacturing processes.

Increased Flexibility

Industrial robotics automation offers increased flexibility to manufacturers by enabling adaptive technology and versatile robotic solutions.

By integrating industrial robotics automation into their production processes, manufacturers can enhance efficiency and productivity. The ability to reprogram robots quickly and easily allows for seamless transitions between different tasks, making processes more agile.

The diverse applications of robots in manufacturing, such as assembly, welding, painting, and packaging, demonstrate the versatility that automation brings to the industry. Manufacturers can customize robotic solutions to suit their specific needs, contributing to a more efficient and adaptable production environment.

The capability of industrial robots to collaborate with other smart technologies, like artificial intelligence and IoT, facilitates adaptive technology integration that optimizes operations and decision-making processes.

Enhanced Data Accuracy and Collection

Industrial robotics automation ensures enhanced data accuracy and collection through advanced software and hardware solutions, optimizing decision-making processes.

By incorporating sophisticated sensors and data analytics capabilities, industrial robots can gather real-time production data with utmost precision, offering valuable insights for managers and operators. This seamless integration of automation technology not only boosts operational efficiency but also reduces the margin for human error, leading to higher overall product quality and adherence to industry standards.

Enhanced Safety Measures

Industrial robotics automation prioritizes enhanced safety measures in industrial settings by deploying robots and automation solutions that minimize risks and ensure worker well-being.

One of the key aspects of safety enhancement in industrial robotics automation involves integrating collision detection systems on robots to avoid accidents. These smart systems use sensors to detect any potential collisions with objects or humans, allowing the robot to adjust its path or stop altogether. Additionally, safety fencing and barriers are crucial elements in creating safe zones for robots to operate without endangering workers nearby. By implementing these safety protocols and advanced technologies, companies can significantly reduce workplace injuries and improve overall operational safety.

Challenges and Disadvantages of Industrial Automation

While industrial automation offers significant benefits, it also presents challenges for manufacturing companies, ranging from initial implementation costs to skill set requirements.

One of the major challenges faced by companies when implementing industrial automation is the substantial upfront costs involved in acquiring and setting up the necessary technology and equipment. These costs can include purchasing the automation systems, integrating them into existing manufacturing processes, and training personnel to operate and maintain the automated systems effectively. The investments required can be prohibitive for many businesses, especially smaller enterprises with limited financial resources.

The Future of Industrial Automation and Robotics

The future of industrial automation and robotics looks promising as technology providers continue to innovate and integrate advanced solutions for enhanced operational efficiency and productivity.

One of the key trends shaping the landscape of industrial automation is the increasing adoption of artificial intelligence (AI) and machine learning algorithms. These technologies enable machines to learn from data, adapt to new situations, and make decisions with minimal human intervention. This transformative shift towards AI-driven automation is set to revolutionize industries by delivering predictive maintenance, autonomous operations, and real-time data analytics.

FAQs about Industrial Robotics Automation

Here are some commonly asked questions about industrial robotics automation, covering topics such as its benefits, implementation planning, and technology selection.

One benefit of incorporating industrial robotics automation is the significant increase in efficiency and productivity. Robots can perform tasks with precision and consistency, reducing errors and operational costs. Companies can also enhance workplace safety by automating hazardous processes.

When considering implementation, it is crucial to develop a thorough plan that aligns with organizational goals and requirements. Technology selection plays a vital role in determining the success of automation projects. Factors such as the type of robots, sensors, and control systems need to be carefully evaluated to ensure optimal performance.

Understanding Industrial Automation

To grasp the concept of industrial automation, it is essential to understand its role in optimizing tasks and processes within industrial sectors.

In the realm of industrial automation, the integration of machine learning algorithms and IoT devices plays a pivotal role in the smooth functioning of operations, resulting in enhanced productivity and reduced human intervention. By automating repetitive and time-consuming tasks, businesses can allocate valuable human resources to more strategic and creative endeavors, fostering innovation and growth.

Furthermore, automation systems enable real-time data monitoring and analysis, offering immediate insights that aid in decision-making for continuous process improvement. This data-driven approach not only enhances operational efficiency but also ensures consistent quality and compliance with industry standards.

Explaining Industrial Robotics

Industrial robotics involves the application of robotic solutions to enhance manufacturing processes, streamline operations, and improve overall efficiency.

These sophisticated machines are utilized in various industrial settings to carry out repetitive tasks with precision and speed, such as assembly, welding, painting, packaging, and material handling. Industrial robotics plays a pivotal role in increasing production output, reducing labor costs, and ensuring consistent quality control. The seamless integration of automation technologies like sensors, machine vision, and artificial intelligence allows robots to adapt to changing production requirements swiftly, resulting in enhanced flexibility and adaptability in manufacturing environments.

Differentiating Robotics and Automation

While robotics and automation are interconnected, they differ in their specific roles within production lines and industrial operations.

In terms of robotics, it involves the use of programmable machines that can carry out tasks with precision and efficiency. These robots are designed to handle repetitive tasks that may be hazardous or require extreme precision in engineering and assembly processes.

On the other hand, automation focuses on the control systems that enable the operation of machinery and processes in an industrial setting. Automation streamlines production by reducing human intervention, enhancing workflow efficiency, and ensuring consistent output quality.

Conclusion

Industrial robotics automation holds immense potential for transforming manufacturing processes by leveraging advanced robotic technology to enhance operational efficiency and productivity.

The integration of industrial robots into manufacturing facilities not only streamlines production but also ensures precision and consistency in tasks. These robots can handle repetitive and dangerous tasks with ease, reducing the risk of injuries to human workers. Furthermore, robotic automation allows for continuous operation, leading to increased output and cost savings. Alongside this, robots are crucial in data collection and analysis, providing insights for process optimization and predictive maintenance.

Frequently Asked Questions

What is Industrial Robotics Automation?

Industrial Robotics Automation refers to the use of robotic systems and technology to automate industrial processes and tasks, reducing the need for human labor and increasing efficiency and productivity.

What are the benefits of Industrial Robotics Automation?

Industrial Robotics Automation offers numerous benefits, including increased productivity, improved product quality, reduced labor costs, and enhanced workplace safety.

How does Industrial Robotics Automation work?

Industrial Robotics Automation involves the use of sensors, cameras, and computer programs to control robotic systems and perform tasks such as assembly, material handling, welding, and painting.

What industries use Industrial Robotics Automation?

Industrial Robotics Automation is used in a wide range of industries, including automotive, electronics, food and beverage, pharmaceuticals, and aerospace, among others.

What are the different types of Industrial Robotics Automation?

There are several types of Industrial Robotics Automation, including traditional robots, collaborative robots, mobile robots, and automated guided vehicles (AGVs).

What skills are required to work with Industrial Robotics Automation?

Professionals working with Industrial Robotics Automation require a combination of mechanical, electrical, and programming skills, as well as an understanding of industrial processes and safety protocols.